Navigate Your Construction Business Efficiently with Top-Quality Aftermarket Construction Parts

Navigate Your Construction Business Efficiently with Top-Quality Aftermarket Construction Parts

Blog Article

Increase Efficiency With Aftermarket Components: a Guide for Heavy Equipment Owners

Benefits of Aftermarket Components

Proprietors of heavy machinery can delight in numerous benefits by opting for aftermarket components over initial tools manufacturer (OEM) components. Aftermarket parts are usually extra budget-friendly than OEM parts, enabling equipment proprietors to lower upkeep and repair work expenses without compromising on top quality.

Because aftermarket manufacturers specialize in generating certain parts, machinery proprietors have access to a more comprehensive range of alternatives to suit their needs. Aftermarket parts are understood for their quality and reliability, with lots of conference or exceeding OEM standards.

Lastly, selecting aftermarket parts can additionally lead to faster repairs and lowered downtime. With less complicated accessibility and fast shipping options, machinery proprietors can obtain their equipment up and running again promptly, decreasing disruptions to their operations.

Choosing the Right Aftermarket Parts

When thinking about aftermarket components for hefty machinery, it is vital to prioritize compatibility and high quality to make sure optimum performance and durability of the tools. Picking the appropriate aftermarket components can be a critical decision for heavy machinery owners as it directly impacts the performance and dependability of their tools.

Secondly, top quality must never be jeopardized when choosing aftermarket parts (aftermarket construction parts). Going with high-quality components makes sure resilience, dependability, and general performance of the equipment. It is recommended to source aftermarket components from credible suppliers or providers understood for their quality requirements

Additionally, considering factors such as service warranties, consumer evaluations, and compatibility with existing systems can additionally aid in making the right option. By prioritizing compatibility and quality when picking aftermarket components, heavy equipment proprietors can enhance the performance and durability of their devices.

Installation and Upkeep Tips

For efficient operation and durability of heavy equipment, proper installation and regular maintenance are extremely important. When mounting aftermarket components, make certain that you carefully adhere to the supplier's guidelines to assure optimum efficiency. By focusing on setup and maintenance procedures, you can optimize the effectiveness and life expectancy of your heavy machinery, ultimately conserving time and cash in the long run.

Cost-Effectiveness of Aftermarket Parts

Proper installment and routine maintenance are foundational aspects for hefty equipment owners aiming to analyze the cost-effectiveness of aftermarket components for their devices. While original tools maker (OEM) parts are known for their top quality, aftermarket components provide a more cost-efficient option without jeopardizing performance. The cost-effectiveness of aftermarket components ends up being apparent in numerous methods. Aftermarket components are typically extra cost effective upfront, permitting owners to attain savings on first purchase prices. Furthermore, these parts commonly provide similar performance to OEM parts, ensuring that the machinery runs efficiently without the requirement for expensive replacements. The availability of aftermarket components from a vast range of vendors advertises competitors, leading to competitive pricing and additional price financial savings for owners. By thoroughly reviewing the quality and compatibility of aftermarket parts with their machinery, owners can strike an equilibrium in between cost-effectiveness and efficiency, inevitably making best use of the efficiency and longevity of Check Out Your URL their heavy devices.

Making Best Use Of Performance With Aftermarket Upgrades

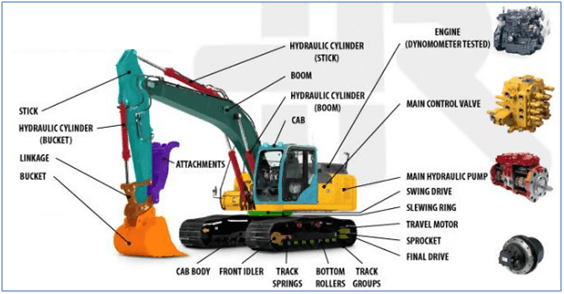

To improve operational performance and efficiency, heavy equipment proprietors can successfully make best use of effectiveness through strategic application of aftermarket upgrades. Aftermarket upgrades supply the opportunity to customize heavy machinery to details functional needs, resulting in boosted capability and output. Upgrading parts such as engines, transmissions, hydraulic systems, and tracks can significantly improve the overall performance of the equipment.

Regularly analyzing the performance of heavy equipment and identifying areas where aftermarket upgrades can be beneficial is vital for making the most of effectiveness. By purchasing quality aftermarket components and upgrades, equipment proprietors can achieve higher degrees of performance, ultimately causing set you back financial savings and improved operational results.

Verdict

In conclusion, aftermarket parts use countless benefits for heavy machinery owners, including cost-effectiveness, boosted effectiveness, and personalization alternatives. By picking the right aftermarket parts, following appropriate installment and maintenance procedures, and making the most of upgrades, heavy equipment owners can enhance their tools's performance and visite site longevity. Buying aftermarket components can inevitably bring about enhanced performance and lowered downtime, making it a worthwhile factor to consider for proprietors aiming to maximize their machinery procedures.

Proprietors of hefty machinery can delight in various advantages by choosing for aftermarket components over initial devices manufacturer (OEM) components. Aftermarket parts are typically a lot more inexpensive than OEM parts, enabling machinery proprietors to minimize maintenance and repair work costs without jeopardizing on quality. By very carefully assessing the quality and compatibility of aftermarket parts with their equipment, owners can strike an equilibrium between cost-effectiveness and efficiency, inevitably maximizing the effectiveness and durability of their hefty tools.

In final thought, aftermarket parts provide countless benefits for heavy equipment owners, consisting of cost-effectiveness, boosted effectiveness, and modification alternatives. By choosing the appropriate aftermarket components, complying with proper installment and maintenance treatments, and maximizing upgrades, heavy machinery owners can enhance their equipment's efficiency and long life.

Report this page